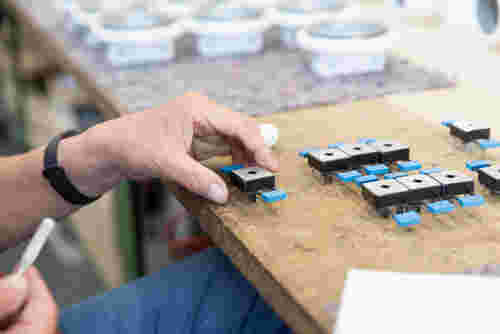

We are proud to manufacture our Superwind generators in Brühl near Cologne, Germany. Our corporate culture is characterised by transparency and flat hierarchies, resulting in very low staff turnover. We rely on the knowledge and experience of our long-standing employees. All components, whether manufactured in-house or by our partners, are subject to strict incoming inspection. Depending on the model, the individual components are assembled at their assembly stations to form the key components of the generator unit and rotor hub. The generator units, rotor hubs and rotor blades are subjected to intensive functional and load tests on special test benches. Each machine is given a unique serial number and is fully documented.

Quality to perfection

Our quality standards are high - we strive to be the best we can be. Over 30 years of experience in the design and construction of small wind turbines has gone into our products. Our generators are specially designed for the marine environment and offer excellent corrosion protection. We use seawater resistant aluminium, anodised and powder coated, and stainless steel even for the ball bearings.

Our attention to detail ensures a high quality end product. We offer an integrated concept, where the wind turbine and the rotor blade adjustment together with the charge controller form a functional unit. The plastics used are UV resistant which, together with the robust construction, ensures the longevity of our products.