Patented blade adjustment

Similar to large wind turbines, the rotor blades of all Superwind generators are automatically adjusted above the nominal wind speed, and the aerodynamic loads are limited directly at the rotor. High forces on the structure are avoided, significantly increasing safety and reliability. At the same time, a Superwind continues to generate full power well above the nominal wind speed: situations in which other wind turbines have to be shut down.

The adjustment mechanism is maintenance-free, fully protected and integrated into the hub. The purely mechanical operation works reliably even in the event of external malfunction and keeps the wind turbine in a safe operating state, independent of electronic components.

Generator shaft

At the heart of the SW 353 is a robust, triple-bearing generator shaft. This design reliably absorbs the increased gyroscopic forces that occur in turbulence and ensures exceptional bearing stability and durability, especially in turbulent locations or in the event of imbalance, e.g. due to ice build-up on the rotor blades.

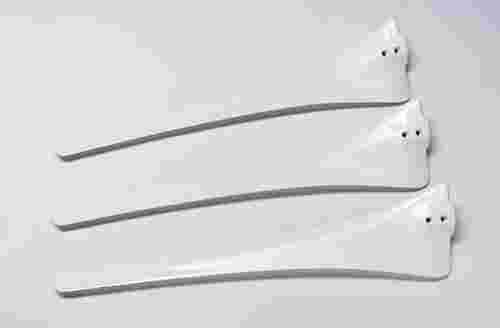

Rotor blades

Hand-laminated GRP-CFRP composite rotor blades further enhance robustness and improve control characteristics.

Damped wind tracking

The wind vane tracking system is designed to reliably turn the wind turbine into the wind when there is sufficient wind to generate electricity. The Superwind generators are equipped with a damping system to ensure that they always track into the wind, even in turbulent locations. The damping of the wind vane also prevents unwanted oscillations caused by waves on buoys or ships.

Star Hub

Star Hub is the rotor hub design of our current wind generators. The patented rotor blade adjustment works fully automatically at high wind speeds, regulates the output above the nominal wind speed and limits the load on the generator. This synchronisation of the rotor blades makes all Superwind turbines more resistant to strong winds and turbulence compared to older technologies.

Other features:

In addition, the units are equipped with a stainless steel mast mount, which allows a fixed bolted connection to the mast tube for maximum stability.

Coordinated overall concept

Because we develop our systems in-house, all components are perfectly matched. The electric generator, for example, is precisely matched to the aerodynamics of the rotor and delivers charging current even at low wind speeds. Designed as a brushless synchronous machine and powered by neodymium magnets, the generator has outstanding efficiency across the entire power range.

While conventional generators have to shut down when the wind is too strong, the rotor blade adjustment and the generous dimensions of the generator ensure that the Superwind generators can deliver full power at all times, even at very high wind speeds.

| Rated power | 350 W | Generator | Permanent magnet, 3-phase, with rectifier, Neodymium magnets |

| Rated wind speed | 12,5 m/s | Nominal voltage | 12 V, 24 V or 48 V, depending on the model |

| Operating range | 3,5 m/s - 35 m/s (unbraked) | Speed control | Rotor blade pitch control |

| Survival wind speed | 50 m/s (braked) | Power control | Rotor blade pitch control |

| Rotor diameter | 1,20 m | Break | Generator short circuit |

| Rotor blades | 3 | Total weight | 12,5 kg |

| Rotor blade material | Hand-laminated GRP-CFRP | Rotor thrust, operating | 70 N |

| Rotational speed | 500 – 1300 rpm | Rotor thrust, extreme gust | 220 N |

Please use our contact form if you would like further information or a quote.